Discover the sustainable methods behind our spirits.

As stewards of the American Whiskey industry, we have a longstanding belief that it’s our responsibility to care for the natural resources we use to craft our spirits. That way, we can help ensure there’s high-quality Whiskey on shelves for many generations to come. With this goal in mind, we focus on sustainability in everything we do, from building our distilleries to creating educational programs—and everything in between. So naturally, we were very proud to be awarded the first ever ENERGY STAR EPA certification for our Bernheim Distillery last year.

WHAT IS ENERGY STAR EPA CERTIFICATION?

You’ve probably seen the Energy Star logo on your household appliances: the little blue star you might find on a dishwasher or refrigerator that lets you know the machine is energy efficient. This certification is our version of that blue star; following a test, the Environmental Protection Agency (EPA) recognizes the best performing plants in each industry.

This test, the Energy Performance Indicator (EPI), measures the performance of a manufacturing facility against its industry on a national level. In order to pass, the plant must score a 75 or higher.

The process continues with an on-site review with an engineer, and finally a compliance screening. This rigorous testing takes months, and few distilleries meet all qualifications. Across the United States, only eight distilleries were awarded the ENERGY STAR EPA certification—and Bernheim Distillery was one of them.

“We have done so much work to make our plant more efficient in the past few years,” says Rachel Nally, director of environment and sustainability at Heaven Hill Distillery.

“Receiving this honor was a nice confirmation that the work we’ve done has paid off, and that our efforts to improve the efficiency of our plant are moving in the right direction.”

BUILDING A BETTER BERNHEIM

At our Bernheim Distillery, some of our upgrades have included switching to LED lighting, improving condensers to reduce water usage, reducing boiler emissions and implementing composting and office recycling programs. “All of these projects, whether large or small, are all crucial and contribute to our sustainability objectives,” Nally says.

When we acquired Bernheim Distillery in 1996, we refurbished it to better fit our operations—and we’re still making updates where we can. In the past year, Heaven Hill Distillery transitioned the last still to evaporate cooling water. Previously, the water would flow into the boiler feed tank and overflow into the drain. Now, thanks to the system upgrade, we can precisely measure how much water is needed to fill these tanks: reducing overflow and preventing extra water from being washed away. Already we’ve seen a massive decrease in wastewater—over 40%!

MANAGING NATURAL RESOURCES

Improving environmental friendliness is a value deeply embedded in everything we do—not just in running our distilleries. Although we already use local grain at our Bernheim Distillery, we took this process one step further with our newest line of Whiskeys: Heaven Hill Grain to Glass. We partnered with Kentucky-based Peterson Farms to grow the grain, and one of their fields is right across the street from our rickhouses. It doesn’t get more local than that!

Outside of our distilleries’ operations and sourcing grains, we’re working to have a positive impact on all aspects of the Whiskey-making process—right down to the forests growing the white oak trees that will become our barrels. Alongside one of our cooperages, Independent Stave Company, we’ve pioneered the Master Logger Program, which is a voluntary training program that educates loggers on best practices for harvesting these trees and protecting the health of the forests. With more informed loggers, we’ll be able to create “a healthier forest and healthier white oak—for Bourbon and for many other industries, as well,” according to Susan Wahl, vice president of American Whiskeys at Heaven Hill Distillery.

In addition to these programs, we’re also committed to using sustainable resources in our products, like the cork we use to craft our bottle stoppers. Cork bark is a naturally renewable material that’s both environmentally and economically sustainable. Since harvesting the bark doesn’t harm the tree itself, they can continue to grow for up to 250 years.

WHAT’S NEXT?

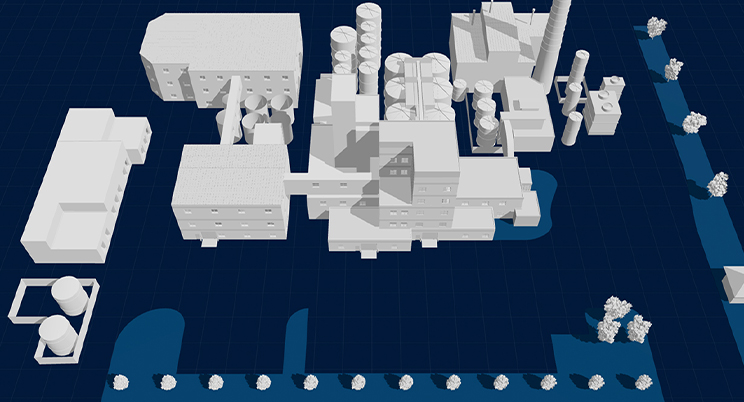

We’re excited to be opening the new Heaven Hill Springs Distillery early next year in Bardstown. Since this is a new build, we’ve been able to bring in the latest technology from the ground up. Each step of the Whiskey-making process has been thoughtfully crafted to promote sustainability, including: insulated column stills to conserve energy, using a wastewater pre-treatment to fuel a generator, planting 600 oak trees…and so much more. So keep an eye out for more about this new distillery as we gear up for production—we can’t wait to share all the details with you!

Of course, we’re always looking for ways we can be more mindful of how we use our resources. This means more programs and innovative ways to improve our distillery operations. One thing is for sure: at Heaven Hill Distillery, our unwavering commitment to sustainability is just as important as our dedication to crafting award-winning American Whiskey. And when we combine the two, we’ll be able to keep lifting spirits for generations to come.